Quick installation shower trays

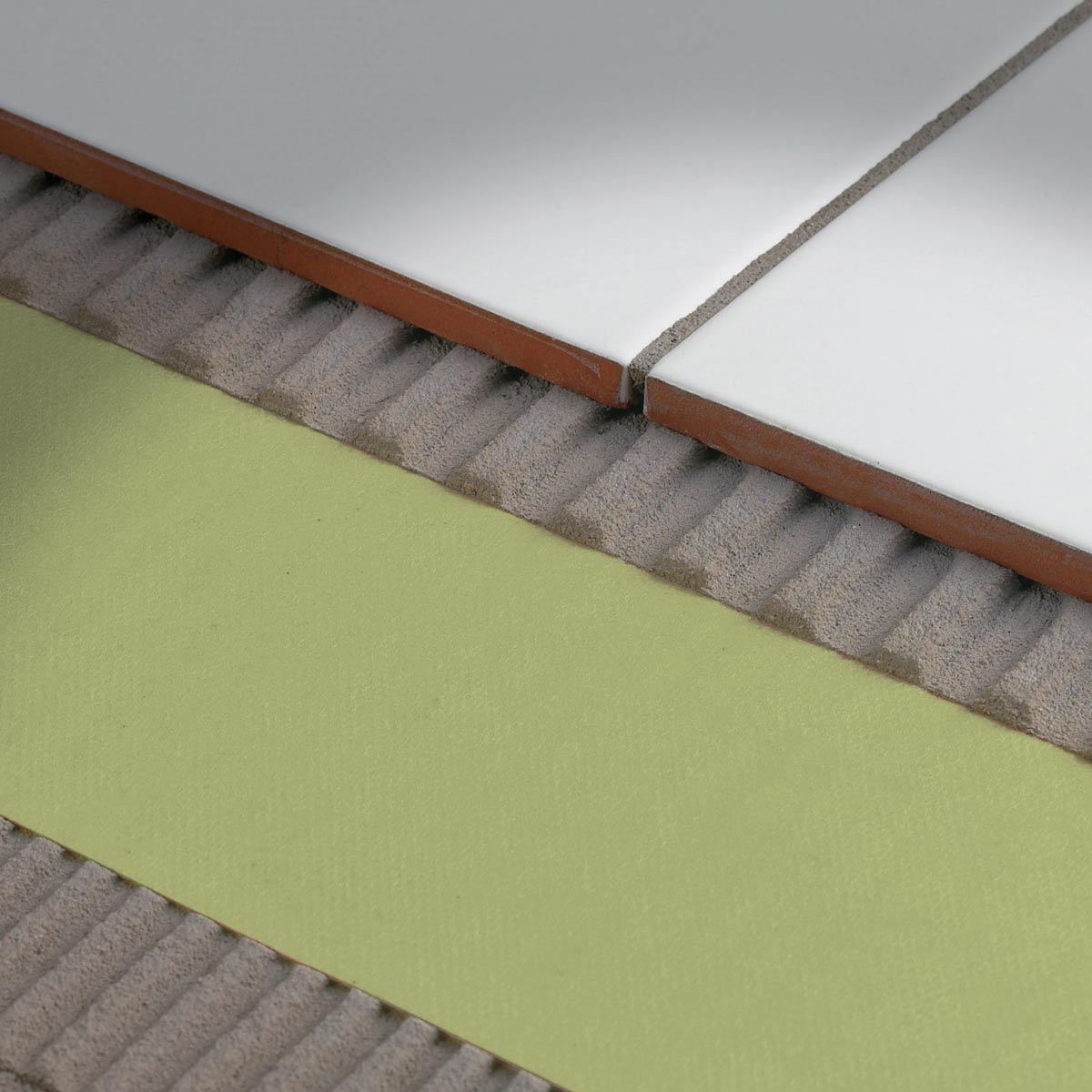

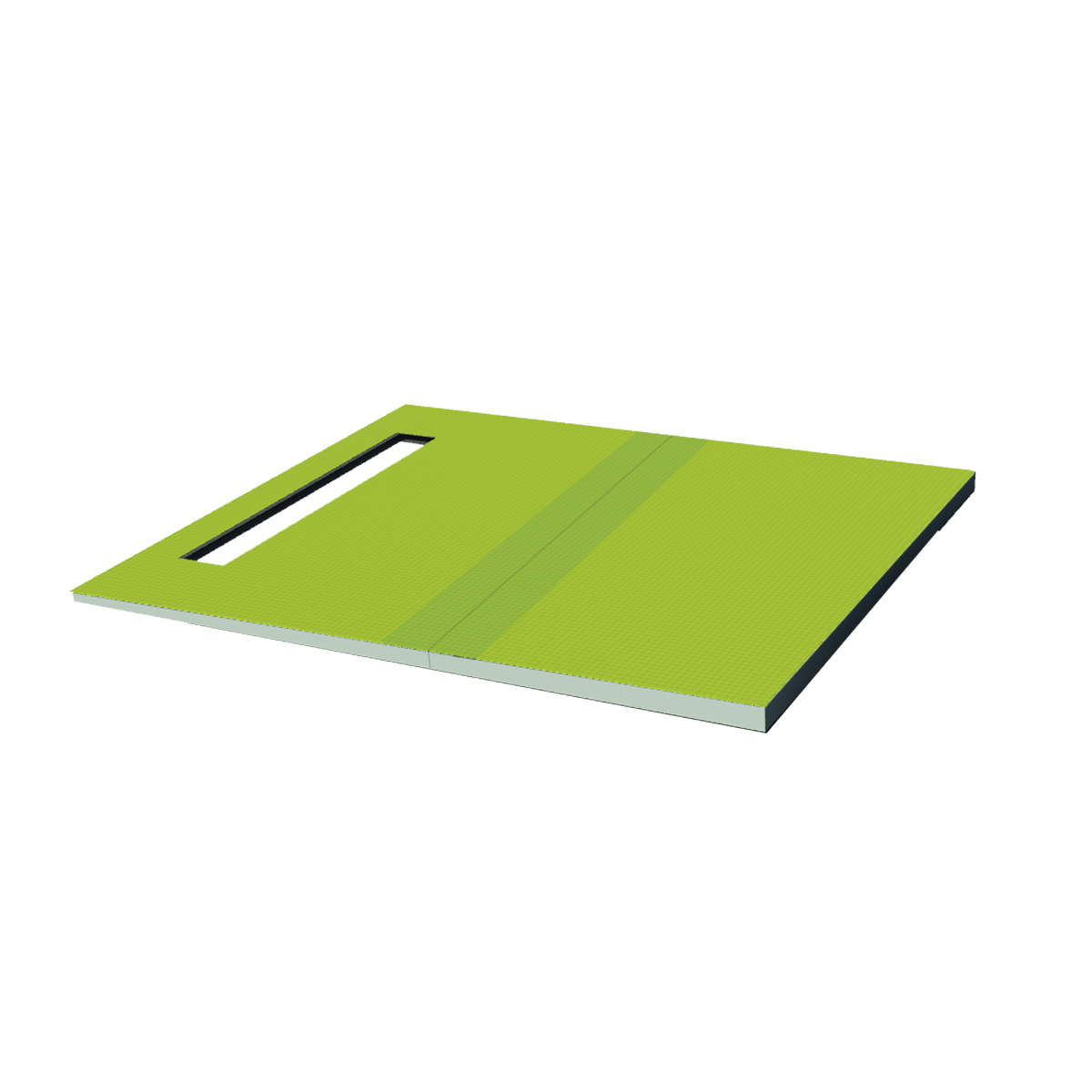

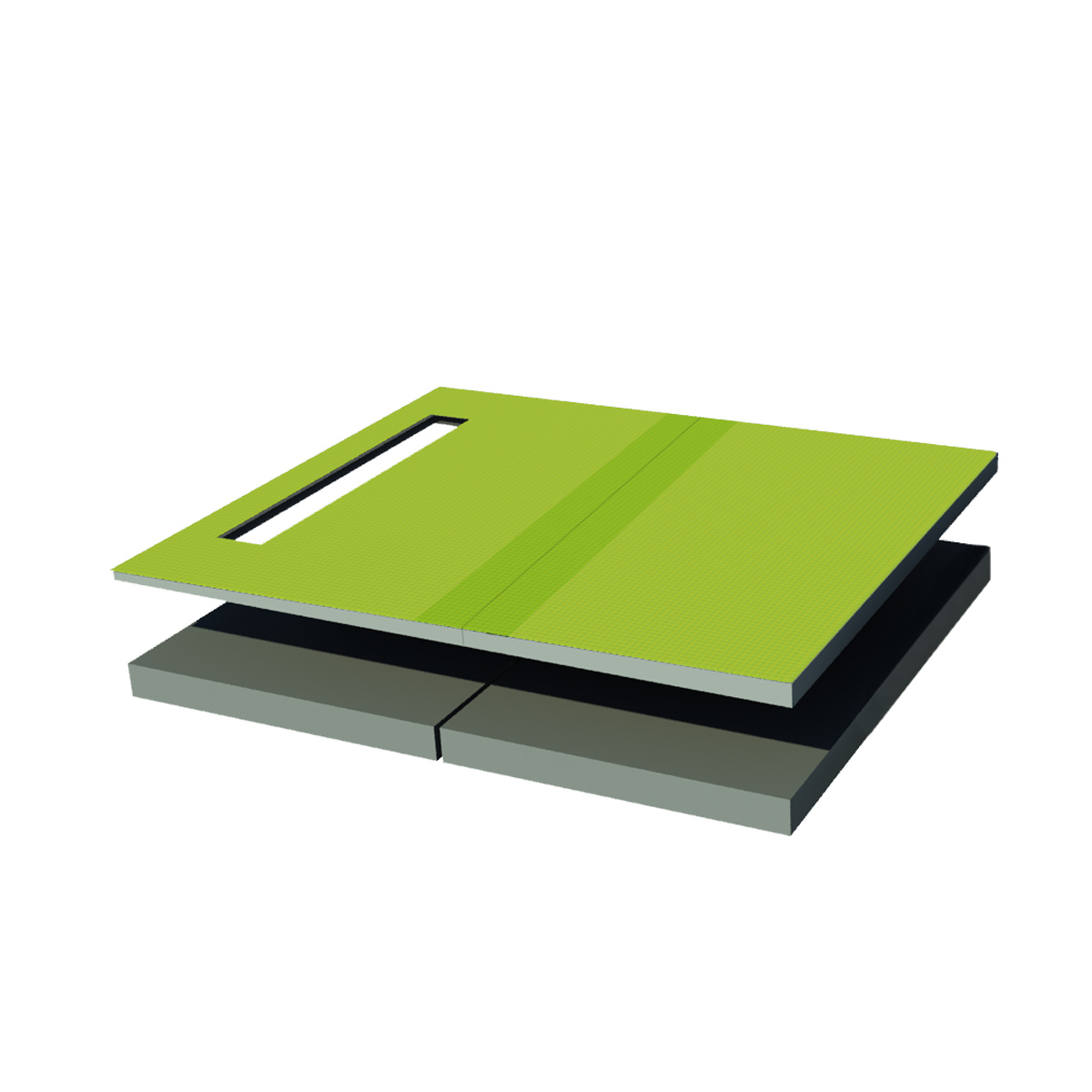

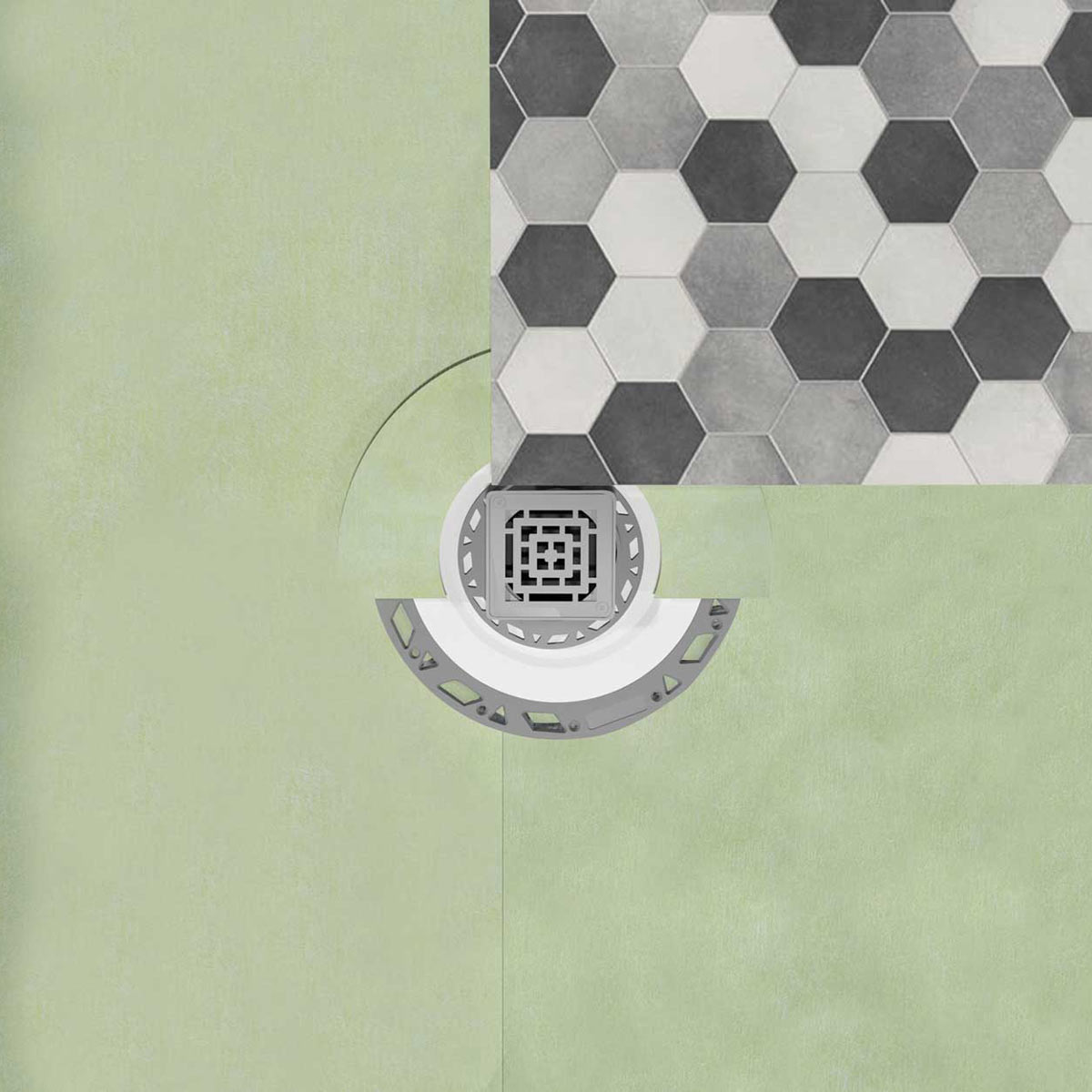

When designing a floor level shower, you need to understand how to make the dish. There are several options: - traditional screed: in this case it is essential that a person who is very capable and experienced performs the work, as he must carefully calculate the slope necessary for a rapid and effective run-off. He must be able to make a screed in a work of art to avoid finding himself at work finished with a plate that has an uneven or worse wrong slope. With this option it is also necessary to take into account the drying times of the screed before proceeding with the waterproofing and then again with the coating; - ready-to-hang dish to be embedded and glued in the floor in corian, acrylic, acrylic stone, and more. The disadvantage is that depending on the type of dish, it can resonate empty and in others it can move creating cracks in the lateral joints with the risk of infiltrations. Furthermore, with this option the continuity effect with the floor will not be created; - Shower Tray, for the unloading point, and the Showertec Linear STL Trays, for the linear one. The first mentioned are flat in EPS, while the second are in XPS, both waterproofed and already sloped and ready to be tiled.The big advantage of these trays is that there is no risk of mistaking the slope, they must simply be placed in the appropriate space dug into the floor with a flat bottom and glued with cement glue, and the laying times are reduced to the maximum, as it will only need wait for the drying times, generally 24 hours, of the areas to be waterproofed.Then you can move on to laying the cladding, from mosaic to stone.